Reasons to Conduct a Manufacturing Performance Audit

The manufacturing audit process is considered to be one of the most comprehensive and cost-effective ways to ensure that the vendor is reliable enough to carry on with the work. It is important to assess as well as re-assess the work efficiency of the existing suppliers. Checking the good quality products is important specially when you are planning to continue work with them. Recent changes inform us that the supplier evaluation chain includes several additional benchmarks that give robust insights on the ways that the factories are managed. It is important to understand the reasons for checking the manufacturing audit performance and how it helps owners from making the mistake of choosing a wrong factory. A wrong factory leads to bad quality products and this, in turn, affects the market reputation.

Verifies the Legitimacy of Suppliers – Factory audits need to be from reputable quality control firms because that is the best way to minimize uncertainties. These uncertainties are primarily because of the risks involved with bad quality products. It is indeed difficult to verify a supplier’s claim from afar and that is when you feel the need to conduct audits. Quality audit in Myanmar is the best way to find out whether the factory is legal and has the required license to sell products.

Confirms the Product Expertise of Suppliers – The best bit about manufacturing audit is the fact that it can look inside the factory’s showroom even without stepping inside. The quality control auditor can verify the machines to check the production capacity of the factory. It is important to know the production processes involved in making the products.

Checks the Capacity of the Factory – In-depth supplier evaluation is important and gives confirmation that the factory is efficient enough to give the required production lead. The supplier’s storage capacity is also crucially checked by the auditor. It is important to keep the semi-finished products and the finished products separate. This minimizes confusion of loading the semi-finished products along with the finished ones. Manufacturing audit informs how well organized the factory management is because that helps in solving all major problems.

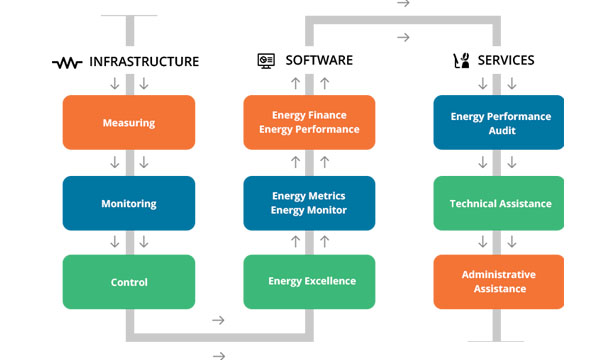

Factory audits are important to have better clarity on the performance of suppliers and the kind of quality the products manufactured by those factories will have. Checking the factory and its infrastructure is important because that gives you a fair idea about the product quality. Manufacturing audit is important because it helps to understand the organized patterns of the production processes.