Product Testing Methods Followed by the Product Testing Companies in Guangzhou

There are many companies that manufacture various kinds of products and distribute them in the market. Now, the most crucial task which runs parallel with the manufacturing unit is the testing of these products to ensure that they are of good quality. We all know that a company is known for the products it manufactures and any defect in them can tarnish the image of the company at one go. Now, we all know that it takes years to build a reputation in the market and a second to ruin all the hard work. So, needless to say, that maintaining the standard is indispensable to sustain in the industry.

Well, if a company fails to maintain the quality of the production, then the competitor of the organization may be beneficial. So, the brands present in the industry try their best to keep up to the standard for recognition in the world of corporate. Hence the testing methods play a major role in building the reputation of a company. To know more in details about them, keep reading below:

Waterfall methodology- Now, this is the method of testing that is followed after the completion of the production but before release in the market. Well, this particular stage involves uncertainty as one defect detected at this stage may incur a heavy loss on the company. For instance, if 40% of the products are detected defective, the rest 60% will fall short and it will bring a huge loss on the company which no one desires. This methodology can be conducted for the expert companies who are a pro in the field than the start-ups. Basically, this is a method that is adapted by the specialists in the industry based on the years of their experience.

Agile methodology- This testing is conducted as soon as the functioning requirement is developed. Now, this is the most suitable method to conduct a scrutiny of the quality of the product and saves the company from major losses if any. This method is followed once the materials are gathered for the production that ensures the quality production from the initial stage to the end. And this is apt for the newcomers in the industry. This saves a lot of time, effort and money.

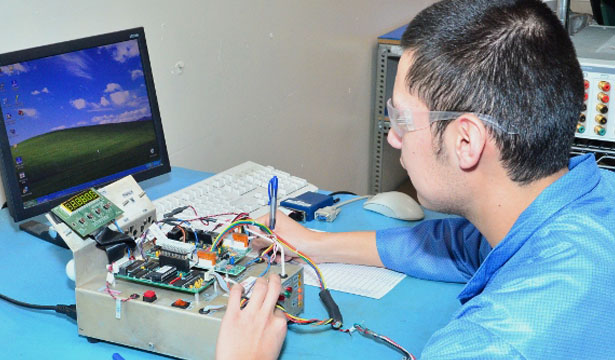

Apart from the above-mentioned methodologies, the environment testing is also significant. This is because when a product is made, the environment in which it is used is taken into consideration. So, here appears the picture of software, hardware and life sciences environment where the product is tried and tested before distributing it in the market. So, with all these testing methods, a product is released in the market that in return adds to the reputation of the company.